Page 1 of 2

Win brass?

Posted: Tue Dec 26, 2006 8:27 pm

by race4hills

How is the Win brass been lately? I know that thier was a problem with necks spliting and Skipper was anealing his cases . Have they gotten better? I want to use a different case for my new gun to make it easer to keep them separate for the two guns. I use Remington for the vssfII.

thanks Lyle

Posted: Tue Dec 26, 2006 9:19 pm

by Matthew

I have not had any of the win brass split at the neck but I do anneal as per Skipper and it works great the only thing I found though is that the primer pockets need to set a bit deeper.

Matt

Posted: Wed Dec 27, 2006 5:44 am

by WHISTLEPIG

I use WW brass. My original lot of 400 cases has been fired and prepped four times and is ready for the fifth loading. I annealed for this loading although I had no split cases. I am currently working on another lot of 1100 cases. This group was a bit longer from the factory and allows a trim length of 1.839. The raw cases run from 1.840 to 1.847. Of course the primer pockets need to be unified and there is a nasty burr on each flash hole. I have completed 400 as far as turning the neck. They just need to have the final neck sizing. A .0012 neck thickness gives about a 75-80 percent clean up. I have handled a total of 900 of the cases. I’m still doing primer pockets on the balance and have only discarded two cases so far: One for an anomaly on the case neck and another for an inclusion in the primer pocket at the flash hole.

I believe I got some ok brass with this lot, although I’m not completely through with the prep. The deal from Midway on the lot of 1100 with no shipping fee made the cost very reasonable and it is good to have all the same run number.

Posted: Wed Dec 27, 2006 7:01 am

by Rick in Oregon

I'm still using my original lot of 500 WW cases without any problems whatever. No rejects at all. All cases have been match prepped but no neck turning, and none have been annealed.

To date, some have been fired and re-neck sized 3 times without any failures of any kind. The necks were all uniform within .0015", so I felt neck turning was unnecessary. Actual neck thickness runs about .015" on WW cases in .204 caliber. As all factory brass is annealed prior to leaving the factory, I usually don't anneal till I either see a split neck or about the sixth firing/reloading....so far so good.

(For the record, I DO anneal all wildcat cases after all case prep and forming is complete, and prior to fireforming.)

Posted: Wed Dec 27, 2006 7:45 am

by skipper

I don't have confidence in the .204 Winchester brass as it is in the bagged condition. I had a lot of split necks before I started annealing them. I guess that you have to make a decision depending on what you intend to do with them. If I was going to load them for a hunting trip, I wouldn't worry about case prep or neck splitting. On the other hand, if I was going to the range or for some LONG range shooting I would probably go completely anal and prep a set of match grade ammo. After I have neck turned, uniformed primer pockets, deburred flash holes inside and out, trimmed to exact lengths, weight sorted, etc., I don't want my work to go to waste. The brass I use for this type of shooting represents a lot of time and effort. I anneal all my Winchester brass that gets the complete treatment to make sure my efforts aren't wasted. Annealing is probably the most fun part of the entire process anyhow. I know that all brass is supposed to be annealed from the factory but, I'm sure that not all manufacturers have the same quality control procedures. The only brass that I don't bother to anneal right out of the box/bag is the Nosler and Norma. They both seem to be just right and require little or no other preparation prior to loading. The good news is that I use Winchester, Hornady and Remington to shoot tight groups with great success. I just prep them all to the exact same specs.

You can test brass to see if it is annealed properly with a pair of vice grips. Set the vice grips so they just deform the case neck. If the brass is annealed properly it should spring back to it's original shape. If it is not, it will stay bent. Also pay attention to just how much pressure it takes to clamp on the case necks. Try this the first time with a case that has been fired many times and one that has just been annealed. Continue slightly closing the vice grips each time you repeat until the annealed case will not spring back to its original shape. You should see a huge difference in the elasticity of the two cases. The fired brass will quit springing back long before the annealed brass does.

Posted: Wed Dec 27, 2006 9:16 pm

by race4hills

Thanks for info guys. I will be getting 500 WW cases from Midway and see what happens. I have not done any anealing yet, but I am going to have to sooner or later anyway. I will be getting my 22-250 rebarreled to a 22-250ai with an 1-12 twist. I do not want my work or new barrel go to waste. May have more questions then.

Anneling

Posted: Sun Dec 31, 2006 6:58 pm

by 95roadking

How do you guy's annel??? Can I do it with my soldering torch???

Posted: Tue Jan 02, 2007 4:20 am

by skipper

95roadking

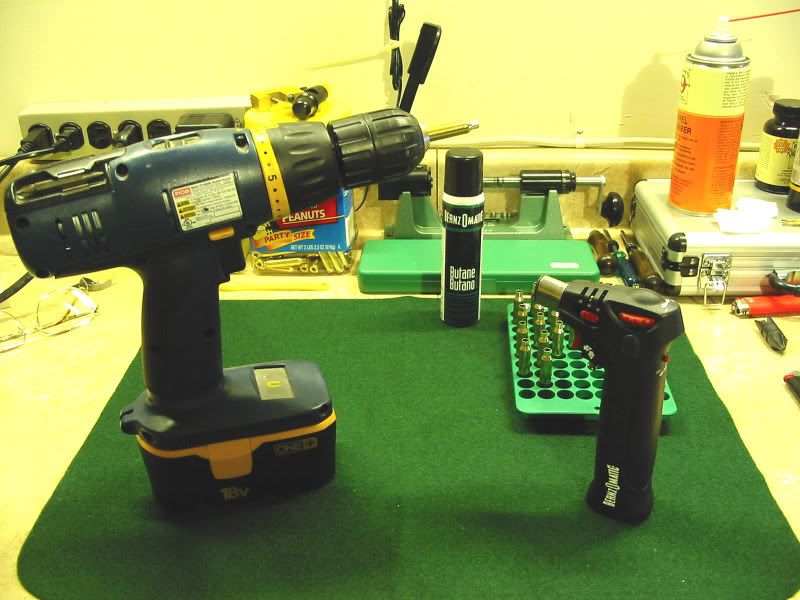

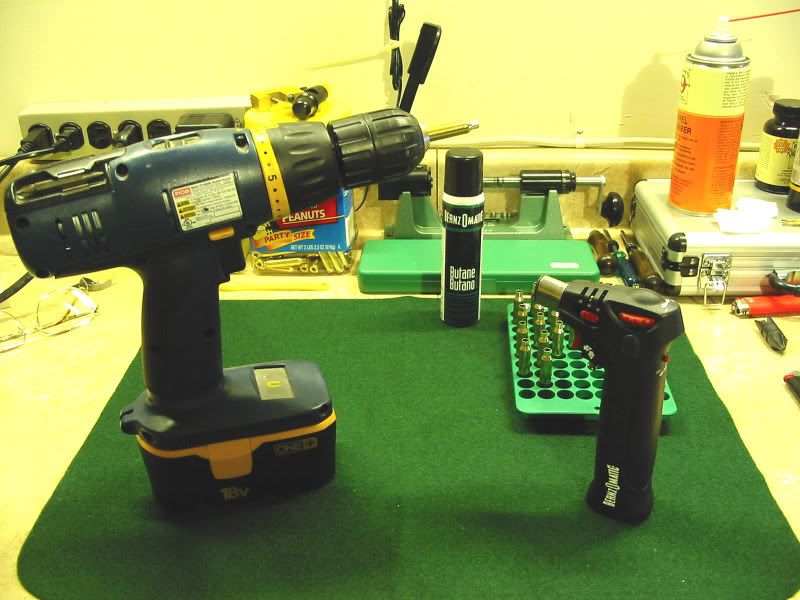

I use the small BernzOmatic torch pictured below. The 3/8 in. socket driver bit chucked up in the drill allows me to spin the case. I can change cases with a leather work glove on my left hand.

Posted: Tue Jan 02, 2007 8:38 am

by Ray P

I' ve been using winchester brass in a custom chamber. I've not been aneeling my brass. Got 4 times around on my 1st 100 peeces and lost 5 pieces that split between the shoulder and neck. I'd say it could be both working harding and bad brass. primer pockets are still tight so were good to go for 5 times. I've lost some factory loaded 34 grn brass on the first shot that split at the neck. I have to say a flaw in the brass.

For the price I don't think winchester brass is a bad deal even if you loss a few pieces.

Later and hope this helps

Ray P

Posted: Tue Jan 02, 2007 1:55 pm

by acloco

Skipper,

What do you use to know that you are in the right temperature range?

Excellent setup. You must have a little "McGyver" in you as well.

I LOVE to get the job done accurately, with the least expense, and with items already owned. EXCELLENT idea.

Posted: Tue Jan 02, 2007 4:54 pm

by skipper

I use a 650 degree temperature sensitive crayon from McMaster-Carr.

Posted: Tue Jan 02, 2007 6:04 pm

by acloco

Skipper - thanks for the info. A temp stick. Will be putting that on the list.

You are hereby dubbed...... MacSkipper!! LOL!

Posted: Wed Jan 03, 2007 4:03 pm

by Hawkeye Joe

I think Winchester adds 5 bad cases to every bag of 100

.After sorting out the bad ones, they have been trouble free throughout 8 loadings.Other than that,No problems at all.

Skipper

Ever check to see how uniform the hardness is after annealing??

Posted: Wed Jan 03, 2007 6:50 pm

by acloco

Hawkeye Joe - I think you have pegged that EXACTLY right.

Posted: Wed Jan 03, 2007 9:46 pm

by gwglave

I'm not sure about Winchester adding 5 bad ones to every bag......I bought a bag of 100 about 5 months ago that had nine cases which had "crinkles" in the necks. In fact, when I first looked at them, they looked like grease dents from putting too much case lube on the outside of the case necks.

I sent them back to Winchester and they sent me a coupon for $20 to buy another bag of brass. All in all not so bad as I only lost nine cases and got another bag for free (I guess that makes up for all the lost time and correspondence and shipping costs?)

Anyway, I took advantage of the deal Midway had a while back on the 1100 Winchester cases. They arrived in 11 individual bags and different lot numbers than the "crinkled" ones. Haven't run into any bad ones from this lot yet. But I've only used 100 of these cases so far and didn't want to open all 11 bags and sort through them all.

Good luck and safe shooting!

Rgds, Gerry